FOOD PRODUCTION TECHNOLOGY

Blencor is a state of the art Blending, Enrobing and Packing facility with highly advanced Frozen Food technology, that provides unique sourcing opportunities from all over the world to ensure a consistent source of supply. Always guaranteeing High Quality and Food Safety.

OUR PRODUCTION PROCESSES

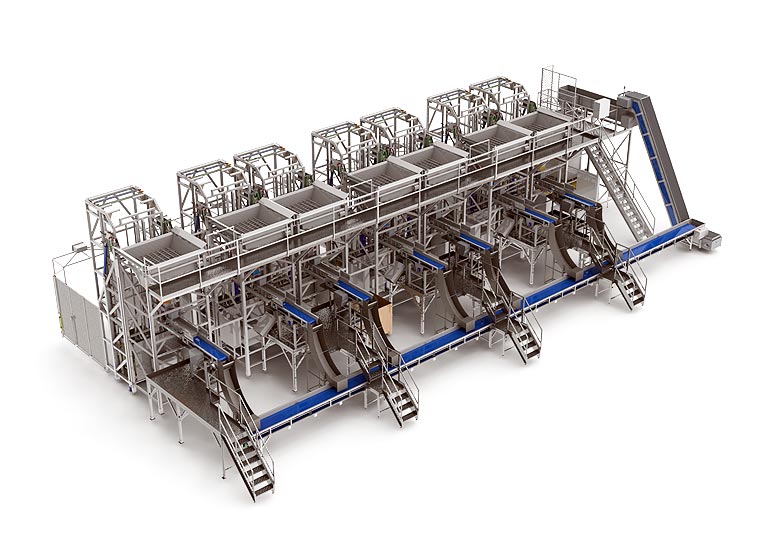

Our facility offers advanced, efficient, precise blending technology. This custom built equipment enables us to simultaneously blend up to 7 different ingredients. The system controlled weight conveyors and scales ensure the highest level of accuracy and consistency in every blend, ensuring that formulations are maintained stable within each ingredient. This high output, precision driven equipment can process thousands of blended pounds a day in a controlled temperature environment, following the Food Safety standards in a completely sanitized ambiance.

The enrobing equipment was custom made to ensure a high level of precision in enrobing capabilities for IQF ingredients that utilize oil and seasoning blends. With this application we can coat each individual component IQF when applying nitrogen and provide an end result of a truly enrobed product with consistent texture, flavor and color. The enrobing tumbling system guarantees that extremely small quantities of liquid and seasoning will be simultaneously applied with precision and evenly spread on each individual component of the blend. This results in the creation of a unique, complex, high-quality product. Customers are able to develop lines of products of higher standards, on-trend, uniformly flavored and of unique formulations.

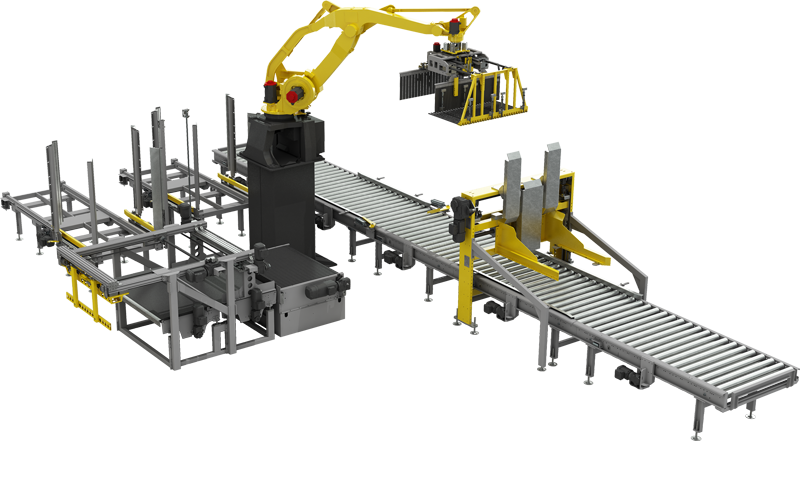

Blencor’s packing lines are equipped with artificial vision technology for detecting foreign materials, dynamic scales for checking individual bags as well as packed cartons, and metal detectors. They are fully automated, equipped with state of the art robot technology. Our packing area, like all other areas of our facility, operates at 35 degrees Fahrenheit.

BLENCOR FOOD TECHNOLOGIES

- Mixing Lines

- Optical Sorter

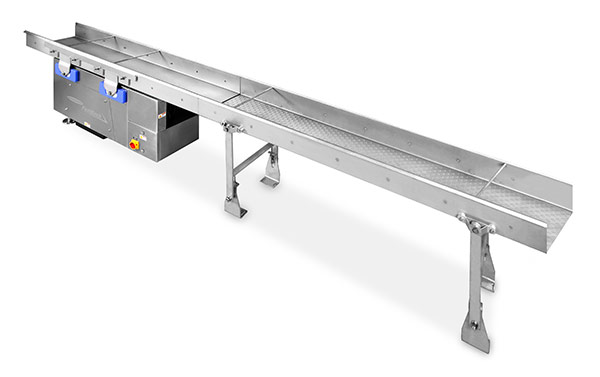

- Horizontal Motion Conveyors

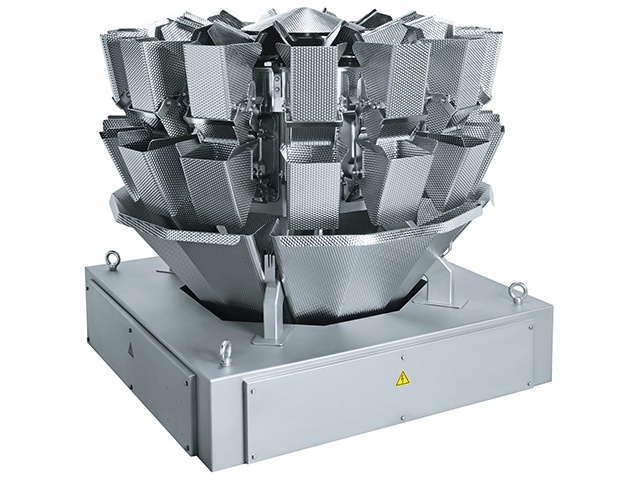

- Multi-head weighers

- Smartpackers

- Packing System

- Robot Palletizer Arm

In addition to its sturdy mechanical construction, this equipment is also noted for its operating accuracy, guaranteeing minimum deviations in relation to the required formula. The mixing lines can either be fed by hydraulic or mechanical tippers, which can receive the product at different heights either by forklift truck or pallet jack.

The optical sorter featuring a small footprint and sorting high throughputs per hour. It detects color defects and foreign materials including glass and plastics.

This multihead weigher strikes the balance between impressive durability and rigorous quality control, achieving consistent results for a range of products, from shellfish to salads.

Our palletizing systems are equipped with anthropomorphic robot and guarantee efficiency, reliability and flexibility for all the production lines.

CONTACT US

Feel free to contact Blencor through our contact form, or alternatively through the WhatsApp button on the bottom right hand side of your screen. In order to help us provide the best possible response to your inquiry, please choose from the options below in the contact form, fill out your details, and then click the Submit button.